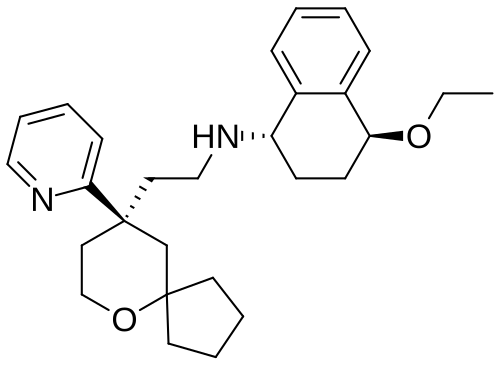

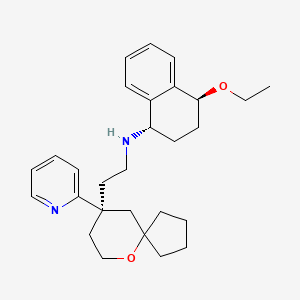

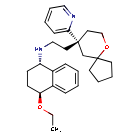

Tegileridine

- YFJS8L4TGU

- CAS 2095345-66-5

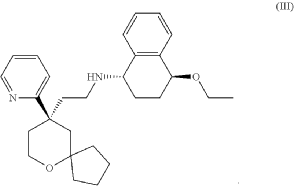

- (9R)-N-((1S,4S)-4-Ethoxy-1,2,3,4-tetrahydro-1-naphthalenyl)-9-(2-pyridinyl)-6-oxaspiro(4.5)decane-9-ethanamine

- 434.6 g/mol

WeightAverage: 434.624

Monoisotopic: 434.293328472

Chemical FormulaC28H38N2O2

(1S,4S)-4-ethoxy-N-[2-[(9R)-9-pyridin-2-yl-6-oxaspiro[4.5]decan-9-yl]ethyl]-1,2,3,4-tetrahydronaphthalen-1-amine

- (9R)-N-((1S,4S)-4-Ethoxy-1,2,3,4-tetrahydro-1-naphthalenyl)-9-(2-pyridinyl)-6-oxaspiro(4.5)decane-9-ethanamine

- (1S,4S)-4-Ethoxy-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro(4.5)decan-9-yl)ethyl)-1,2,3,4-tetrahydronaphthalen-1-amine

- (1S,4S)-4-Ethoxy-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro(4.5)decane-9-yl)ethyl)-1,2,3,4-tetrahydronaphthalen-1-amine

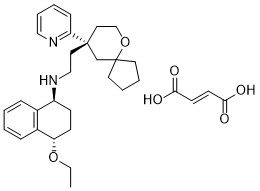

Tegileridine fumarate

CAS#2245827-85-2 (fumarate)

Chemical Formula: C32H42N2O6

Exact Mass: 550.3000

Molecular Weight: 550.70

CHINA 2025, APPROVALS 2025, AISUTE, Jiangsu Hengrui

Tegileridine is under investigation in clinical trial NCT06458400 (To Evaluate the Efficacy and Safety of Tegileridine and Oliceridine Injections in the Treatment of Postoperative Pain).

Tegileridine is a drug which acts as a μ-opioid receptor agonist. It is closely related to compounds such as oliceridine, TRV734, and SHR9352, and shares a similar profile as a biased agonist selective for activation of the G-protein signalling pathway over β-arrestin 2 recruitment.[1]

In January 2024, tegileridine was approved in China for the treatment of moderate to severe pain after abdominal surgery.[2]

SYN

CN107001347

https://patentscope.wipo.int/search/en/detail.jsf?docId=CN203399246&_cid=P20-METU4Y-21400-1

SYN

https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2017063509&_cid=P20-METU6J-22458-1

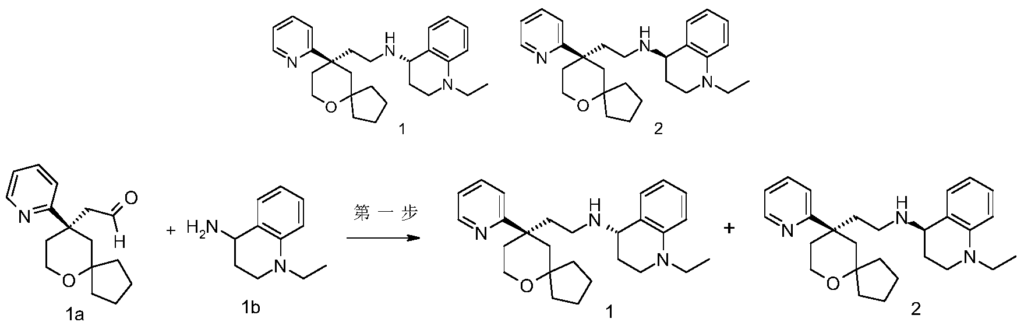

[0184](S)-1-Ethyl-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro[4.5]decan-9-yl)ethyl)-1,2,3,4-tetrahydroquinolin-1-amine 1

[0185](R)-1-ethyl-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro[4.5]decan-9-yl)ethyl)-1,2,3,4-tetrahydroquinolin-1-amine 2

[0186]

[0187](R)-2-(9-(pyridin-2-yl)-6-oxaspiro[4,5]decane-9-yl)acetaldehyde 1a (294 mg, 1.135 mmol, prepared by the method disclosed in patent application “WO2012129495”) and 1-ethyl-1,2,3,4-tetrahydroquinolin-4-amine 1b (200 mg, 1.135 mmol, prepared by the method disclosed in patent application “WO2014078454”) were dissolved in 15 mL of dichloromethane, stirred for 1 hour, and sodium triacetoxyborohydride (1.203 g, 5.675 mmol) was added and stirred for 16 hours. 20 mL of water was added, and the mixture was extracted with dichloromethane (20 mL×3). The organic phases were combined, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated under reduced pressure. The residue was purified by high performance liquid chromatography to obtain the title product, 1-ethyl-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro[4.5]decan-9-yl)ethyl)-1,2,3,4-tetrahydroquinolin-1-amine. Chiral preparation was performed (separation conditions: chiral preparative column Superchiral S-AD (Chiralway), 2 cm ID*25 cm, 5 um; mobile phase: CO

2 :methanol:diethanolamine=75:25:0.05, flow rate: 50 g/min). The corresponding fractions were collected and concentrated under reduced pressure to give the title products 1 (98 mg, brown oil) and 2 (95 mg, yellow solid).

[0190]Chiral HPLC analysis: retention time 4.028 minutes, chiral purity: 99.7% (chromatographic column: Superchiral S-AD (Chiralway), 0.46 cm ID*15 cm, 5 μm; mobile phase: CO2: methanol: diethanolamine = 75:25:0.05 (v/v/v))

[0191]

1H NMR(400MHz,DMSO-d 6)δ8.54(s,1H),7.72(s,1H),7.45(d,1H),7.20(s,1H),6.95(s,1H),6.78(d,1H),6.52(d,1H),6.37(s,1H),3.60(br,2H),3.18-3.43(m,3H),2.99(m,1H),2.33-2.45(m,3H),1.77-1.99(m,3H),1.19-1.60(m,12H),1.00-1.06(m,4H),0.63(m,1H).

[0194]Chiral HPLC analysis: retention time 3.725 minutes, chiral purity: 99.8% (chromatographic column: Superchiral S-AD (Chiralway), 0.46 cm ID*15 cm, 5 μm; mobile phase: CO2: methanol: diethanolamine = 75:25:0.05 (v/v/v))

[0195]

1H NMR(400MHz,DMSO-d 6)δ8.53(s,1H),7.72(s,1H),7.46(d,1H),7.20(s,1H),6.97(s,1H),6.85(d,1H),6.54(d,1H),6.40(s,1H),3.61(br,2H),3.17-3.25(m,3H),3.00-3.01(m,1H),2.33-2.46(m,3H),1.78-1.97(m,3H),1.24-1.65(m,12H),1.01-1.06(m,4H),0.61(m,1H).

SYN

https://patentscope.wipo.int/search/en/detail.jsf?docId=US306969245&_cid=P20-METUA8-25189-1

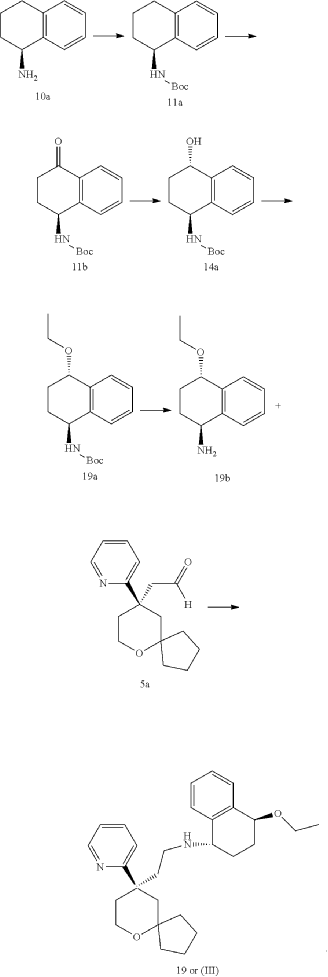

Embodiment 1: Preparation of (1S,4S)-4-ethoxy-N-(2-((R)-9-(pyridin-2-yl)-6-oxaspiro[4.5]decan-9-yl)ethyl)-1,2,3,4-tetrahydronaphthalen-1-amine

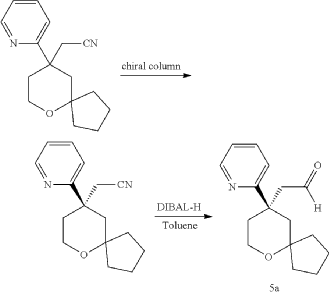

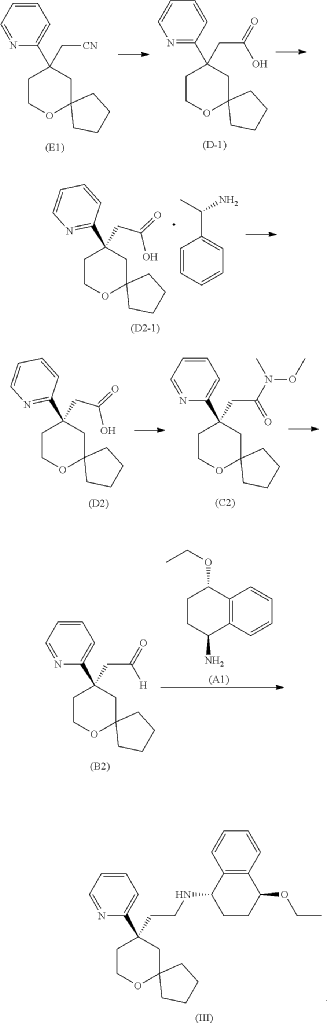

Step One: Synthesis of Intermediate (D-1)

Step Two: Synthesis of Intermediate (D2-1)

Step Three: Synthesis of Intermediate (D2)

Step Four: Synthesis of Intermediate (C2)

Step Five: Synthesis of Intermediate (B2)

Step Six: Synthesis of the Compound Represented by Formula (III)

SYN

SYN

Tegileridine fumarate, developed by Jiangsu Hengrui Pharmaceuti

cals Co., Ltd., is a novel small-molecule analgesic that functions as a

complete opioid receptor agonist with relative selectivity for -opioid

receptors (MOR). It is marketed under the brand name Aisute. In 2024,

the NMPA approved Tegileridine fumarate injection for the treatment of moderate to severe pain following abdominal surgery. Tegileridine ex

erts its analgesic effects by activating MOR, leading to inhibition of

adenylate cyclase activity, decreased intracellular cAMP levels, and

subsequent modulation of ion channel conductance. This results in hy

perpolarization of neuronal membranes and reduced neuronal excit

ability, effectively alleviating pain. The clinical efficacy of Tegileridine

was evaluated in a Phase III randomized, double-blind, placebo-

controlled trial (NCT05012516) involving patients experiencing mod

erate to severe pain after abdominal surgery. The research indicated that

Tegileridine offered substantial alleviation of pain in contrast to the

placebo. It manifested a quick-acting property, and its analgesic effects

endured throughout the period of observation. In terms of toxicity,

Tegileridine was typically well-tolerated by the subjects. The most

frequently encountered adverse reactions were nausea, vomiting, and

dizziness, all of which were of mild to moderate intensity. Importantly,

Tegileridine exhibited a favorable safety profile with a lower incidence

of gastrointestinal adverse reactions compared to traditional MOR ag

onists, potentially offering an improved therapeutic window for post

operative pain management. The approval of Tegileridine provides a

new treatment option for patients suffering from moderate to severe

postoperative pain, particularly following abdominal surgeries,

addressing a significant clinical need in pain management [72,73].

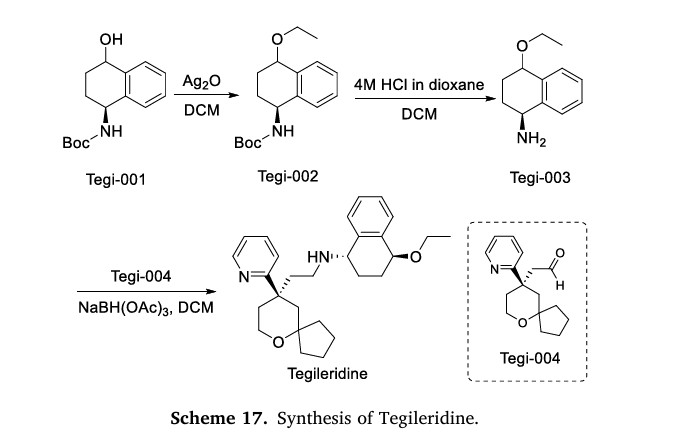

The synthesis of Tegileridine fumarate, illustrated in Scheme 17,

begins with nucleophilic substitution reaction involving Tegi-001 to

yield Tegi-002 [74]. Tegi-002 is subsequently acidified to produce

Tegi-003. Finally, Tegi-003 undergoes reductive amination with

Tegi-004 to synthesize Tegileridine.

[72] S. Dhillon, Correction: tegileridine: first approval, Drugs 84 (2024) 1011.

[73] S. Dhillon, Tegileridine: first approval, Drugs 84 (2024) 717–720.

[74] X. Li, B. Feng, Y. Chen, T. Liu, F. He, M. He, W. Tao, P. Sun, Oxa Spiro Derivative

Useful in Treatment of Pain and pain-related Disease and Its Preparation, 2017.

CN107001347A.

AS ON JUNE2025 4.45 LAKHS VIEWS ON BLOG WORLDREACH AVAILABLEFOR YOUR ADVERTISEMENT

join me on Linkedin

Anthony Melvin Crasto Ph.D – India | LinkedIn

join me on Researchgate

RESEARCHGATE

join me on Facebook

Anthony Melvin Crasto Dr. | Facebook

join me on twitter

Anthony Melvin Crasto Dr. | twitter

+919321316780 call whatsaapp

EMAIL. amcrasto@gmail.com

……

References

- WO 2017/063509, “Oxa spiro derivative, preparation method therefor, and applications thereof in medicines”, published 10 April 2018, assigned to Jiangsu Hengrui Medicine Company and Shanghai Hengrui Pharmaceutical Company Ltd .

- Dhillon S (June 2024). “Tegileridine: First Approval”. Drugs. 84 (6): 717–720. doi:10.1007/s40265-024-02033-4. PMID 38771484.

| Clinical data | |

|---|---|

| Trade names | 艾苏特 |

| Legal status | |

| Legal status | Rx in China |

| Identifiers | |

| IUPAC name | |

| CAS Number | 2095345-66-5 |

| PubChem CID | 129049969 |

| UNII | YFJS8L4TGU |

| Chemical and physical data | |

| Formula | C28H38N2O2 |

| Molar mass | 434.624 g·mol−1 |

| 3D model (JSmol) | Interactive image |

| SMILES | |

| InChI | |

- New drugs approved by the NMPA in 2024: Synthesis and clinical applicationsPublication Name: European Journal of Medicinal ChemistryPublication Date: 2025-07-05PMID: 40262297DOI: 10.1016/j.ejmech.2025.117643

- Tegileridine: First ApprovalPublication Name: DrugsPublication Date: 2024-05-21PMID: 38771484DOI: 10.1007/s40265-024-02033-4

- Study of the mass balance, biotransformation and safety of [14C]SHR8554, a novel μ-opioid receptor injection, in healthy Chinese subjectsPublication Name: Frontiers in PharmacologyPublication Date: 2023-09-14PMCID: PMC10538116PMID: 37781692DOI: 10.3389/fphar.2023.1231102

- Oxa spiro derivative, preparation method therefor, and applications thereof in medicinesPublication Number: US-2018297988-A1Priority Date: 2015-10-15

- Oxa spiro derivative, preparation method therefor, and applications thereof in medicinesPublication Number: WO-2017063509-A1Priority Date: 2015-10-15

- Oxaspiro derivatives, methods of their manufacture, and their application in pharmaceuticalsPublication Number: JP-6824502-B2Priority Date: 2015-10-15Grant Date: 2021-02-03

- Oxa spiro derivatives, their preparation, and their applications in medicinePublication Number: KR-102703513-B1Priority Date: 2015-10-15Grant Date: 2024-09-06

- Opioid Receptor (MOR) Agonist Salt, Its Fumarate Salt I Crystalline Form, and Process for Making SamePublication Number: JP-7153030-B6Priority Date: 2017-04-14Grant Date: 2023-07-24

- Oxa spiro derivative, preparation method therefor, and applications thereof in medicinesPublication Number: EP-3354649-A1Priority Date: 2015-10-15

- Oxa spiro derivative, preparation method therefor, and applications thereof in medicinesPublication Number: EP-3354649-B1Priority Date: 2015-10-15Grant Date: 2019-12-04

- Oxaspiro derivative, process for its production and its application in medicinePublication Number: JP-2018534257-APriority Date: 2015-10-15

- Oxa spiro derivative, preparation method therefor, and applications thereof in medicinesPublication Number: US-10442793-B2Priority Date: 2015-10-15Grant Date: 2019-10-15

////////////Tegileridine, CHINA 2025, APPROVALS 2025, AISUTE, Jiangsu Hengrui, YFJS8L4TGU, 2095345-66-5, Tegileridine FUMARATE