Increasing global access to the high-volume HIV drug nevirapine through process intensification

DOI: 10.1039/C7GC00937B, Paper

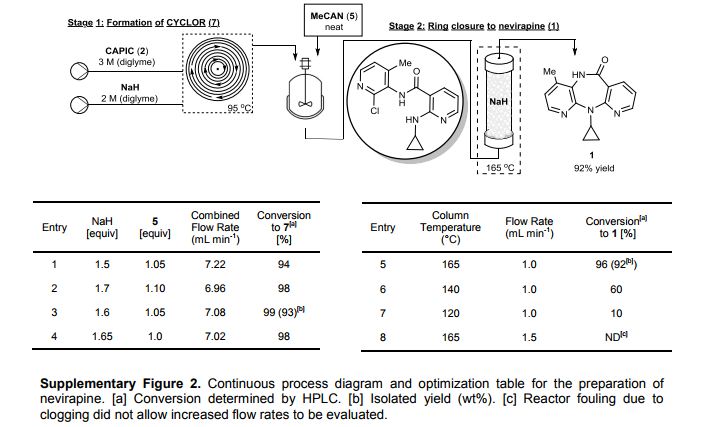

Fundamental elements of process intensification were applied to generate efficient batch and continuous syntheses of the high-volume HIV drug nevirapine.

Green Chemistry

Increasing global access to the high-volume HIV drug nevirapine through process intensification

Abstract

Access to affordable medications continues to be one of the most pressing issues for the treatment of disease in developing countries. For many drugs, synthesis of the active pharmaceutical ingredient (API) represents the most financially important and technically demanding element of pharmaceutical operations. Furthermore, the environmental impact of API processing has been well documented and is an area of continuing interest in green chemical operations. To improve drug access and affordability, we have developed a series of core principles that can be applied to a specific API, yielding dramatic improvements in chemical efficiency. We applied these principles to nevirapine, the first non-nucleoside reverse transcriptase inhibitor used in the treatment of HIV. The resulting ultra-efficient (91% isolated yield) and highly-consolidated (4 unit operations) route has been successfully developed and implemented through partnerships with philanthropic entities, increasing access to this essential medication. We anticipate an even broader global health impact when applying this model to other active ingredients.

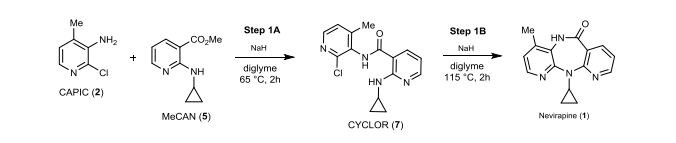

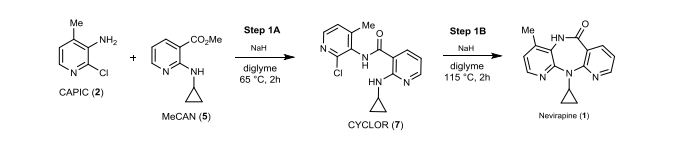

Preparation of Nevirapine (1).

Preparation of CYCLOR (7), Step 1A: To a solution of CAPIC (2, 15 g, 105 mmole, 1.0 equiv) in diglyme (75 mL) in a 500 mL 3-neck round-bottom flask fitted with overhead stirrer, thermocouple, and addition funnel was added NaH (7.56g, 189 mmole, 1.8 equiv). The reaction mixture was stirred at room temperature for 30 minutes and gradual evolution of H2 gas was observed. The temperature of the reaction mixture was slowly increased to 60 °C (10 °C/hr increments). A preheated (55 °C) solution of MeCAN (5, 21.19 g, 192.2 mmol, 1.05 equiv) in diglyme (22.5 mL) was added over a period of an hour to the reaction mixture kept at 60 °C. The reaction mixture was allowed to stir at 60 °C for 2 hours. If desired, 7 may be isolated at this stage. The reaction mixture is cooled to 0 – 10 °C and the pH is adjusted to pH 7-8 using glacial acetic acid and stirred for an hour. The precipitate is collected by vacuum filtration and dried under vacuum to a constant weight to afford CYCLOR (7) (29.89g, 94%).

1H NMR (300MHz, CHLOROFORM-d) = 8.44 (dd, J = 1.8, 5.3 Hz, 1 H), 8.21 (d, J = 4.7 Hz, 1 H), 8.15 (br. s., 1 H), 7.87 (dd, J = 2.1, 7.9 Hz, 1 H), 7.54 (s, 1 H), 7.20 (d, J = 5.3 Hz, 1 H), 6.66 (dd, J = 4.7, 7.6 Hz, 1 H), 2.95 – 2.84 (m, 1 H), 2.35 (s, 3 H), 0.91 – 0.77 (m, 2 H), 0.62 – 0.47 (m, 2 H).

13C NMR (75MHz, CHLOROFORM-d) = 166.8, 159.2, 153.2, 148.3, 146.9, 136.0, 129.9, 125.1, 111.1, 108.4, 77.4, 76.6, 23.8, 18.8, 7.0.

HRMS (ESI) C15H15ClN4O m/z [M+H] + found 303.0998, expected 303.1012.

Preparation of nevirapine (1), Step 1B: In a 150 mL, 3 neck flask, fitted with overhead stirrer, thermocouple and addition funnel, a suspension of NaH (7.14 g, 178.5 mmol, and 1.7 equiv) in diglyme (22.5 ml) was heated to 105 °C and crude CYCLOR (7) reaction mixture from Step 1 (preheated to 80 °C) was added over a period of 30 minutes while maintaining the reaction mixture at 115 °C. The reaction mixture was stirred for 2 hours at 117 °C for ~2 hours then cooled to room temperature. Water (30 mL) was added to quench the excess sodium hydride and the reaction was concentrated in vacuo to remove 60 mL of diglyme. To the resulting suspension was added water (125 mL), cyclohexane (50 mL) and ethanol (15 mL). The pH of the mixture was adjusted to pH 7 using glacial acetic acid (19.5 g, 3.09 mmol) at which precipitate formed. After stirring for 1 hour at 0 °C, the precipitate was collected via vacuum filtration and the filter cake was washed with ethanol: water (1:1 v/v) (2 x 20 mL). The solid was dried between 90-110°C under vacuum to provide nevirapine (25.4 g, 91% over two steps).

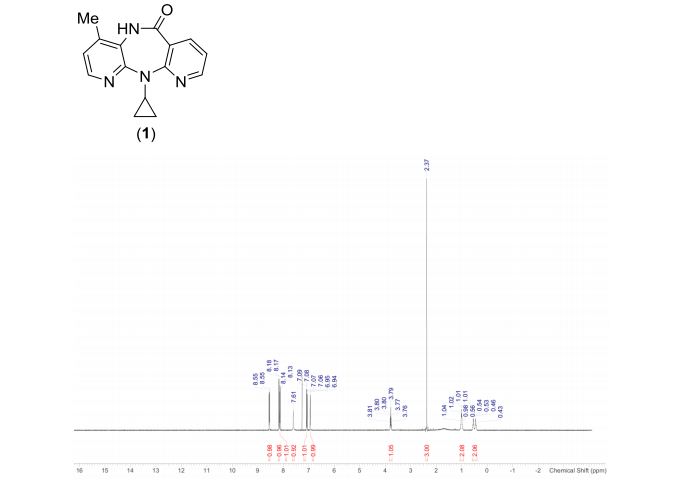

1H NMR (400MHz, CDCl3) = 8.55 (dd, J = 2.0, 4.8 Hz, 1 H), 8.17 (d, J = 5.0 Hz, 1 H), 8.13 (dd, J = 2.0, 7.8 Hz, 1 H), 7.61 (s, 1 H), 7.08 (dd, J = 4.8, 7.8 Hz, 1 H), 6.95 (dd, J = 0.6, 4.9 Hz, 1 H), 3.79 (tt, J = 3.6, 6.8 Hz, 1 H), 2.37 (s, 3 H), 1.07-0.93 (m, 2 H), 0.59-0.50 (m, 1 H), 0.50-0.41 (m, 1 H).

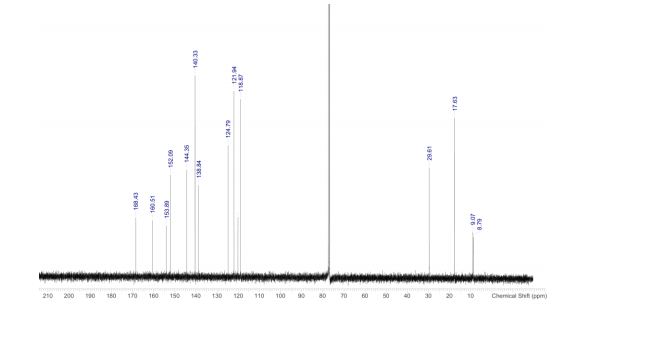

13C NMR (101MHz, CDCl3) = 168.4, 160.5, 153.9, 152.1, 144.3, 140.3, 138.8, 124.8, 121.9, 120.1, 118.9, 29.6, 17.6, 9.1, 8.8.

HRMS (ESI) C15H14N4O m/z [M+H] + found 267.1239, expected 267.1245.

Purification of nevirapine. To a cooled (0 °C) suspension of nevirapine (10g, 375.5 mmole) in water (43 ml) was added a 10 M solution of HCl (11.6 ml, 117.5 mmole) dropwise. The solution was allowed to stir for 30 minutes and activated carbon (0.3g) was added. After stirring for 30 minutes, the solution was filtered over Celite. The filtrate was transferred to flask and cooled to 0 °C. A 50% solution of NaOH was added dropwise until a pH of 7 is reached. A white precipitate appeared and the solution was stirred for 30 minutes and filtered. The solid was washed with water (3 x 10ml). The wet cake was dried between 90-110°C under vacuum to a constant weight to provide nevirapine (9.6 g, 96%).

/////////////