In June of this year, the EMA issued a revision of their earlier Q&A document focused on NORs, PARs, and DSp.(2) First issued in draft form in 2015, this has been revised based on feedback and consultation with industry. The document focuses on five questions, which are summarized below along with a reflection on the answer provided and its implications.

1. What is a Normal Operating Range (NOR) and how should NORs be presented in the marketing authorisation dossier?

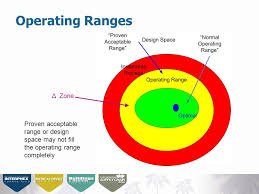

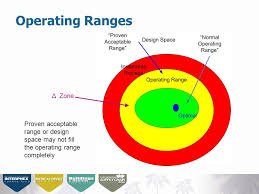

Answer: NOR is not an established ICH term. The NOR describes a region around the target operating conditions that contain common operational variability (variability that can’t always be controlled). A NOR can be established for several process parameters of the same process step, with the understanding that the NOR does not represent deliberate adaptation of the process, and that the NOR does not cover a parameter range that affects the quality of the process output. Otherwise, a PAR or a multivariate Design space should be established. The use of NORs alone is not intended to introduce flexibility in the conditions for manufacturing but to better quantify the actual uncontrollable operational variability of process parameters. NORs should therefore be presented in marketing authorisations as what is practically achievable.

Requests to provide details of NORs have become an increasingly prevalent request from reviewers, predominantly in Europe, the absence of such information being classified as a deficiency. It was noted that the term NOR seemed to have risen to prominence even though this it is not an ICH term. Interestingly the answer draws specific attention to this and concedes this is not a formal ICH term. The framing of this question is interesting and already indicates the EMA thinking by posing the question—how should NORs be presented? the subsequent answer makes very clear NORs should be presented. Is this an issue? Arguably not as many organizations have presented NORs within section S2.2 without challenge. But it makes abundantly clear that this is unlikely to be optional.

So what is an NOR? The document provides the following definition:

An NOR describes a region around the target operating conditions that contain common operational variability (variability that cannot always be precisely controlled to a single and specific value). This is consistent with the thinking of many and should allow the definition of a range which reflects equipment capability. For example, a range of 35 °C ± 5 C° may reasonably be considered an NOR given the variability of the temperature control and calibration systems.

Overall while effectively introducing a “new” term this is an established concept already widely used and thus this is not considered as a significant concern.

What Is a Proven Acceptable Range (PAR) and How Should PARs Be Justified and Presented in the Marketing Authorization Dossier?

Again a specific definition is provided:

The PAR is defined as a characterized range of a process parameter for which operation within this range, while keeping other parameters within set points or NORs, will result in producing a material meeting relevant quality criteria (ICH Q8 R2).

(1)A key phrase within this seems to be the statement that other parameters must be kept constant. Is this ever the reality, and what is constant? Later in the document in the answer pertaining to DSp, there is effective recognition that some form of interrelationship will generally exist. What is perhaps more important is establishing the criticality of this relationship not that one simply exists. Later within the answer it is also stated that where an interaction exists between different parameters, the parameters should be included in a Design Space. One might be forgiven for believing that this may penalize the more diligent applicant who seeks to properly study possible interactions. Missing at present is clarity around what happens if you explore multiple parameters and find no interactions or more likely no “significant” interactions. In such circumstances where the interactions have no impact, it should be possible to justify multiple ranges (or at least a range wider than the NOR).

There is also a need to understand more about when an interaction is significant. If there are no interactions across the ranges proposed and no impact on drug substance quality is demonstrated with multivariate experiments, then surely we do not need a design space—it adds no value and makes no sense.

ref 1

2 Questions and answers: Improving the understanding of NORs, PARs, DSp and normal variability of process parameters, EMA/CHMP/CVMP/QWP/354895/2017.

///////////////Normal Operating Range, NOR, Proven Acceptable Range, PAR, ich, maa